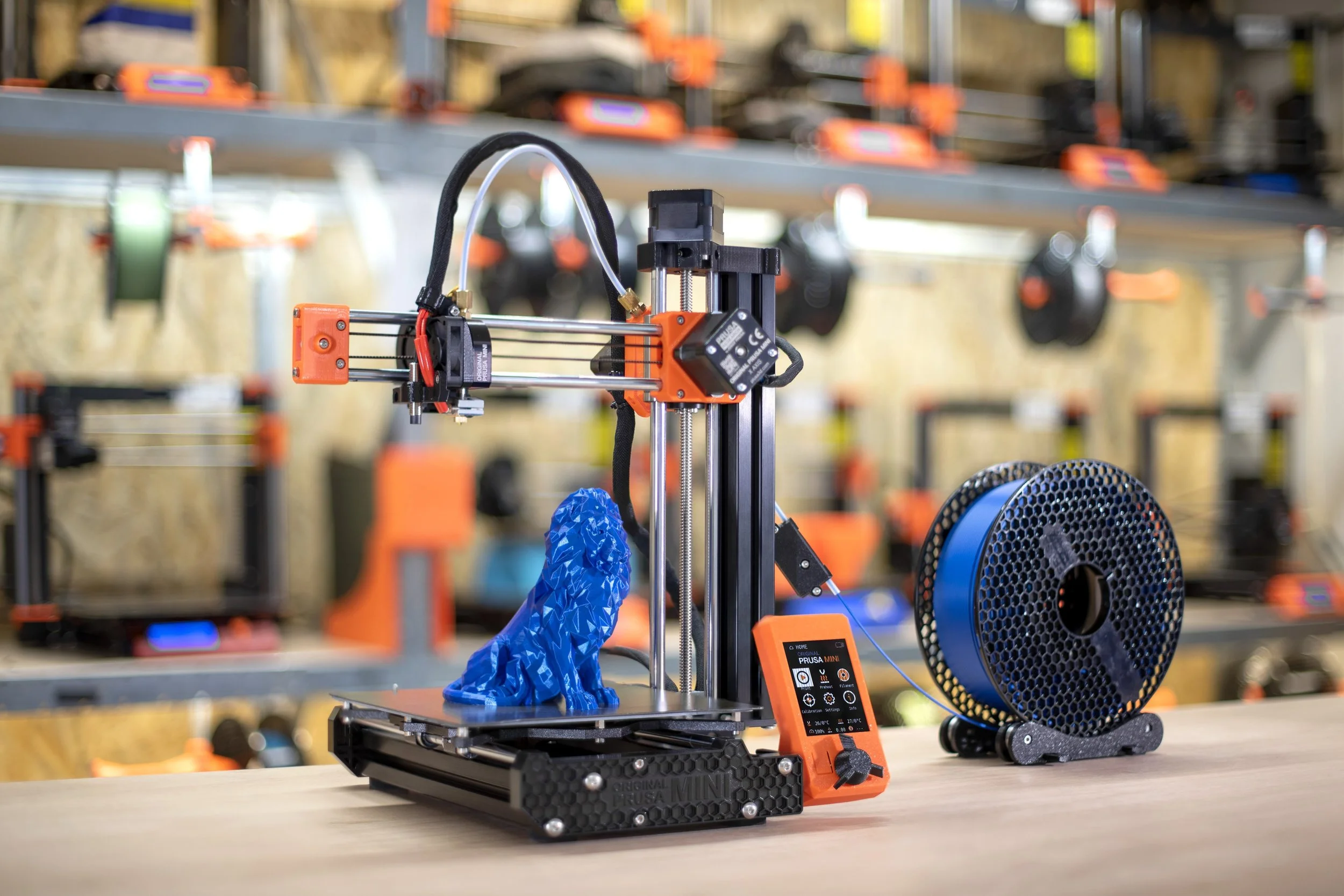

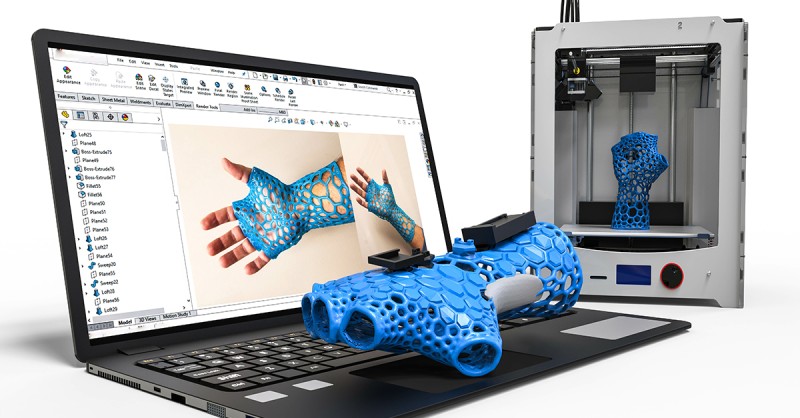

3D printing has transformed how designers, engineers, and makers bring ideas to life. But a brilliant design on screen doesn’t always translate into a flawless 3D-printed model. Optimizing your 3D CAD models for printing is the secret to saving time, reducing waste, and achieving smooth, professional-quality results.

Whether you’re a product designer, hobbyist, or engineer, these best practices will help you prepare models that print successfully every time.

🔑 Why Optimization Matters

- 🚫 Avoid print failures — poorly optimized models may warp, break, or never finish printing.

- 💸 Save time and money — fewer failed prints = less wasted filament/resin.

- 🎨 Improve quality — sharper details, smoother surfaces, and functional strength.

- ⚡ Faster printing — streamlined geometry and smart orientation reduce print time.

🛠️ Steps to Optimize 3D Models for 3D Printing

1. ✅ Ensure Your Model is Watertight

- A “watertight” or manifold model has no gaps, holes, or missing faces.

- Non-manifold geometry confuses slicer software and leads to broken prints.

- Tip: Run a “Check Geometry” or “Mesh Repair” in tools like Blender, Fusion 360, or Meshmixer.

2. 📐 Scale and Wall Thickness

- Thin walls often collapse or don’t print at all.

- Minimum wall thickness:

- FDM printers → ~1.2 mm

- SLA/DLP printers → ~0.6 mm

- Scale your model to match printer capabilities and end-use requirements.

3. 🎯 Simplify Geometry

- Overly complex meshes slow down slicing and printing.

- Use mesh reduction tools to optimize without losing detail.

- Keep polygon count reasonable — especially for decorative parts.

4. 🧱 Add Supports Strategically

- Identify overhangs greater than 45° that may need supports.

- Orient models to minimize supports (saves material + post-processing effort).

- For resin printing → angle parts slightly to reduce suction and layer lines.

5. 🌀 Hollow Large Models

- Solid models use excessive material and take forever to print.

- Hollowing reduces cost and print time.

- Add escape holes to allow resin/filament removal.

6. 🪞 Orient for Strength & Quality

- Print orientation affects layer adhesion and strength.

- Functional parts → align forces perpendicular to layers.

- Aesthetic parts → orient to minimize visible layer lines.

7. 🖌️ Consider Post-Processing

- Design with sanding, painting, or assembly in mind.

- Split models into multiple parts for easy finishing and stronger joints.

⚡ Quick Optimization Checklist

✔ Watertight geometry (no holes)

✔ Adequate wall thickness

✔ Simplified, optimized mesh

✔ Correct orientation

✔ Supports only where needed

✔ Hollow large models with escape holes

✔ Consider post-processing needs

🎯 Final Thoughts

Optimizing your 3D models for printing is more than a technical step—it’s the difference between a prototype that fails halfway through and a part that looks like it came from a professional workshop.

By applying these techniques, you’ll save material, time, and frustration—while producing prints that are both functional and beautiful.